Packaging Technology

Our wide range of packaging systems offer the perfectly tailored solution for your application. When choosing a system for your process that is optimal in terms of efficiency and process technology, many factors are taken into account, such as the required variety of products and outer packaging as well as the setting patterns of the products in the outer packaging. Our portfolio includes simple stacking systems through to fully automated packaging machines in various performance classes. All systems are characterised by high performance, optimal flexibility, compact construction, highest availability and optimal access for cleaning and servicing.

PM1

The new PM1 ensures organised, clean and effective final packaging. Completely overhauled, the 3rd generation of these multi-purpose machines is now available. The simple operation and great ergonomics have been improved even further. Thanks to the easy tool-less belt change, a wide range of products can be stacked on one machine. The stacking height can be freely adjusted and adapted to the filling volume of the outer packaging. There are two variants to choose from: with the stacking belt arranged at 90° or 180°. This makes the machine the optimal solution for lines with constantly changing products and outer packaging.

Special features

- for low and medium throughputs

- PM1-Q: max. 90 products/minute

- PM1-L: max. 110 products/minute

- suitable for all product dimensions

- discharging belt suitable for one or two workers

- tool-less belt replacement (discharging belt)

- integrated transfer belt

- integrated control cabinet

- compact construction

- Open-frame construction

- optimal access for cleaning and servicing

PM2

For over 13 years, the PM2 device series has brought order and efficiency to the outer-packaging sector. The current version comes in two variants. Depending on the application, product format and location, the PM2 can be arranged transversely or parallel to the line. The integrated kinematics ensure that the discharging belt runs slowly and steadily, thereby providing optimal ergonomics. This principle also ensures that even products that are hard to stack can be processed. A clearly arranged TFT touchscreen ensures user-friendly operation. The system controller is compatible with our ZLS line controller and features a future-proof OPC-UA interface for connection with any controller or software. Thanks to the easy tool-less belt change, a wide range of products can be stacked on one machine. The stacking height can be freely adjusted and adapted to the filling volume of the outer packaging. This allows a wide range of products to be handled with minimal changeover times.

Special features

- for medium and high throughputs

- PM2-Q: max. 140 products/minute

- PM2-L: max. 180 products/minute

- suitable for all product dimensions

- discharging belt suitable for one or two workers

- tool-less belt replacement (discharging belt)

- integrated transfer belt

- integrated control cabinet

- compact construction

- Open-frame construction

- optimal access for cleaning and servicing

PM4

The PM4 provides the optimal solutions for creating vertical setting patterns and transferring them into cardboard boxes. The machine can be continuously adjusted to different product formats (optional). The cardboard boxes are supplied prepared and upright – allowing manually prepared boxes as well as automatically prepared boxes to be processed. All machines are individually adapted to the respective product and boxes ex factory. This means that there is always an optimal solution for a wide range of requirements.

Special features

- Output of up to 200 products/minute

- max. 25 boxes/minute

- integrated transfer belt

- continuously adjustable for different product dimensions

- Open-frame construction

- standardised OPCUA machine interface

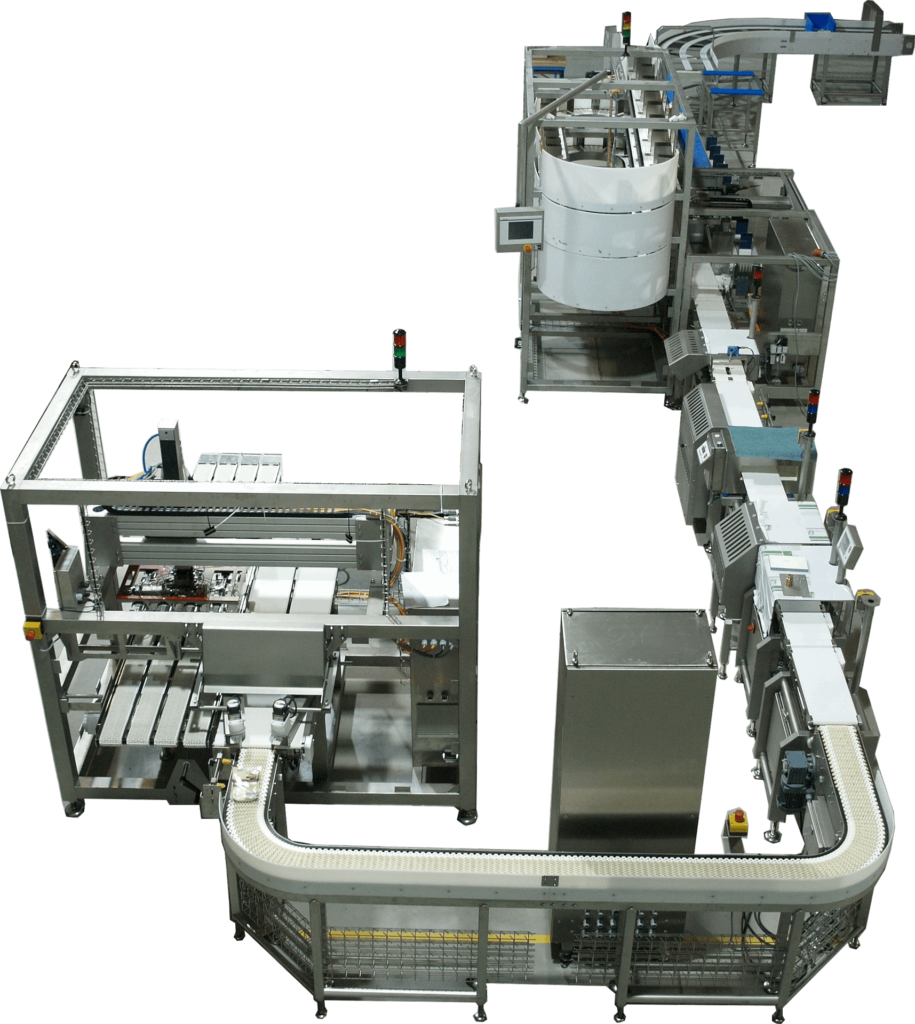

PM6

The PM6 provides the optimal solution for creating horizontal setting patterns and transferring them into cardboard boxes or crates. The machine can process serial product flows of 160 units/minute. Setting patterns and outer packaging are adapted depending on the application. In contrast to flexpickers or other robot-based solutions, the PM6 is based on a powerful portal system, which can pick up several products simultaneously. This protects the products and makes the service life of the machine far superior to other solutions.

Special features

- for product flows of up to 160 products/minute

- filling of crates or cardboard boxes

- tool-less changeover to other boxes or product sizes possible

- energy efficient

- adapted setting pattern

- long service life

- standardised OPCUA machine interface

PM7

The automated secondary packaging of trays can be quickly and flexibly implemented with the PM7. The system can handle up to 90 trays/minute and places them in crates using freely configurable setting patterns. The setting pattern is created in multiple stages and applied though kinematics. Mechanical and vacuum grippers are available for different products and surfaces. These can be swapped via the semi-automatic changing system.

Special features

- Output of up to 90 products/minute

- filling of crates

- tool-less changeover to other crates possible

- suitable for all tray sizes

- energy efficient

- adapted setting pattern

- long service life

- standardised OPCUA machine interface

PR1

The PR1 is perfect for automatic packaging of laying or standing product presentations in crates or cartons. The fast and tool-free adaptation of the system to changing product dimensions, variing packaging patterns and orientations in the carton or crate guarantees maximum flexibility for existing and future packaging requirements.

The project-related implementation of the packaging system is modular and cost-optimized to the specific requirements of your application.

The optical inspection system OI2pro can be integrated to this packaging system which guarantees 100% control of your production quantities immediately before packaging into the cartons or crates.

Special features

- performance up to 70 products / minute / unit

- maximum 20 cartons / minute

- modular arrangement of one or more handling units

- tool-free Tool-Changing-System

- project-related tool

- empty package control

- camera inspection of top AND / OR bottom

- operating side left / right

Have we sparked your interest?

Contact us today at:

- +49 37296 9383 500