You are here:

Start » Products » Metal detection » Plastics & Bulk Materials » Metal detectors for bulk materials (free fall)

Metal detectors for bulk materials (free fall)

Metal detection for quality assurance and machine and consumer protection has become indispensable in virtually every area of industry. Our separators are available in numerous variants and are suitable for any kind of use in virtually all applications. A variety of options, such as wear-resistant, antistatic product pipes, high-temperature designs and specialised models, allow them to be used even under tough conditions.

VA

The separators in the VA series are suitable for all types of bulk material. The device range covers aperture sizes from 25 mm to a maximum of 100 mm and can be combined with the MESEP, Digital2 and M-Pulse2 electronics. The pneumatic ejector flap is suitable for all free-fall applications and reliably rejects all metals. A wear-resistant variant is available for particularly abrasive bulk materials. The device can be optionally fitted with fan or compressed-air cooling for high product temperatures. A compressed-air monitor and automatic flap reset (for power or compressed-air outages) is also available. The stainless-steel design makes the device suitable for applications in the food industry.

Special features

- Maintenance-free mechanism

- Different aperture sizes can be supplied

- Robust pneumatic ejector mechanism

- Electronics suitable for the application can be supplied

- Extensive accessories available

- All devices are mechanically compatible

Compact

Like many separators from Pulsotronic, the Compact series is based on powerful metal detectors and the Digital2 evaluation electronics. Metal residues are removed using compressed air via blast nozzles that are arranged close together under the ring sensor. This makes these models also suitable for backed-up material columns. Its compact construction means that the device is primarily suitable for applications where very little space is available.

Special features

- Maintenance-free separating system

- Different aperture sizes can be supplied

- All devices are mechanically compatible

- Very compact design

- Suitable for backed-up bulk materials

KR / KRS

Separators in the KR series with an aperture of 100 mm to a maximum of 300 mm are available for applications with high throughputs or large parts. The sensors are supplied with a frame for simple installation. Optional ejector flaps in different designs are available for all sizes. Product pipes can also be made from antistatic material if needed.

Special features

- Maintenance-free mechanism

- Very large aperture sizes can be supplied

- Robust pneumatic ejector mechanism (optional)

- Electronics suitable for the application can be supplied

- Models can be supplied with or without ejector mechanism

- Protection class IP65

- Stainless-steel system

- Support frame can be integrated into existing constructions

SE

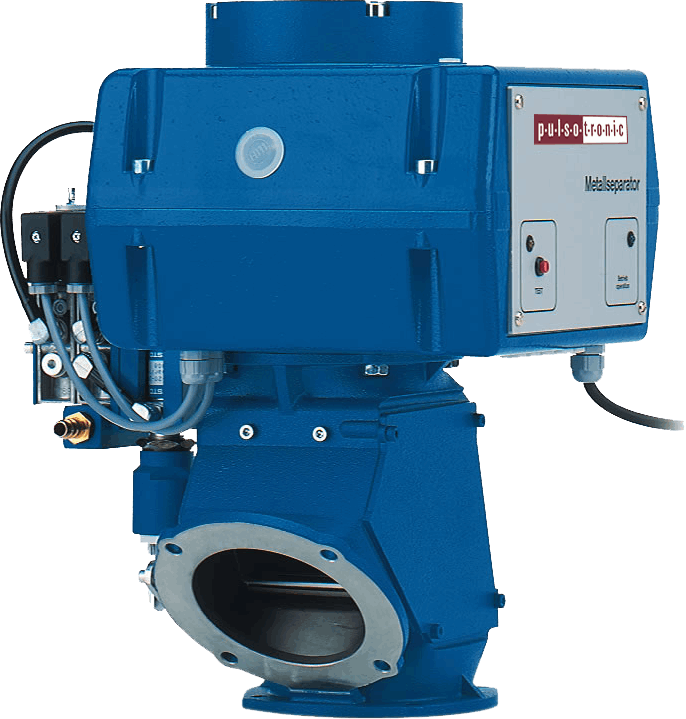

These separators are used for a wide range of applications in the plastics or chemical industry. All the critical machine parts are manufactured from sturdy cast aluminium. This makes the detector indestructible and guarantees a long service life even under adverse conditions.

Special features

- Maintenance-free mechanism

- Different aperture sizes can be supplied

- Robust pneumatic ejector mechanism

- Extensive accessories available

- All devices are mechanically compatible

- Compact design

Y

In many applications – e.g., in injection moulding machines – granulate backlog occurs in conveying lines. This blocks conventional ejector flaps. The Y separator features an ejector mechanism with a unique design that allows switching and rejecting in the flap area even when there is a material jam. Despite its compact design, the ejector mechanism also has sufficient speed to be able to respond fast enough in free-fall applications. In combination with the powerful metal detection, all downstream machines are perfectly protected. It is primarily used to check plastic granulate at injection-moulding machines (machine protection and quality assurance), where the compact separator can be directly installed.

Special features

- Maintenance-free mechanism

- Different aperture sizes can be supplied

- Robust, patented pneumatic ejector mechanism

- Suitable for backed-up bulk materials

- Extensive accessories available

- All devices are mechanically compatible

- Compact design

- Ejection monitoring

Have we sparked your interest?

Contact us today at:

- +49 37296 9383 500